HSS END MILLS

Type of HSS End Mills

PARALLEL SHANK ROUGHENING END MILLS

TAPER SHANK ROUGHENING END MILLS

Wide Range : Diameter – 3mm up to 100mm and Length – 37mm to 800mm

Tolerances : e8 / JS14 / Customer Specific

View catalogCustomers of HSS End Mills

- TATA Motors Limited

- Toshiba JSW Power Sysems Pvt Ltd

- Lucas TVS Limited

- Lakshmi Machine Works Limited

- Premium Transmission Pvt Ltd

- BBL Daido Private Limited

- Diesel Modernisation Works

- EHWA Diamond India Pvt Ltd

- Shanti Switchgears Pvt Ltd

- Tool & Die Industries.

- Pocket Milling / Shoulder Milling in Machine Tool Industries.

- Woodruff cutters– in Automotive / Pump Industries.

GALLERY

• An Endmill is a cutting tool used in industrial milling applications.

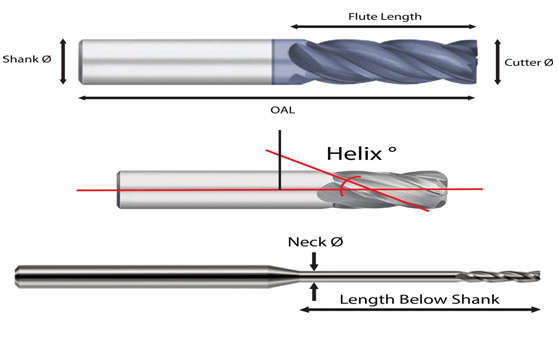

Following are the elements of an Endmill

• Cutter Diameter

• Shank Diameter

• Overall Length

• Flute Length

• Length Below Shank

• Neck Diameter

• Helix Angle

• Flutes

• Variable Helix

• Variable Pitch

• To ensure that you do not damage the material you are attempting to drill into, it is imperative that you have to use the correct drill bit.

• Width of the shank that is held in the toolholder.

• Total length of the tool between both axial ends.

• Functional cutting depth with the tool in the axial orientation.

• Also called the reach, is the length from the neck portion to the end of the cutting end of the tool.

• Diameter of the neck.

• Angle measured from the centreline of the tool and a straight-line tangent along the cutting edge.

• A variable helix Endmill utilizes unequal flute spacing to reduce harmonics which can extend tool life and improve part finish.

• Variable Pitch refers to cutting edge spacing that is unequal.

• By creating an Endmill with unequal pitch between tooths, cutting forces are changed which results in reduced vibration, higher feed rates and better part finishes.

• The spiralled cutting grooves in the tool.

• Fewer flutes allow for larger chips and a deeper cut depth, but are weaker and best suited for plastics and Aluminium.

• More flutes increase the tool strength but reduce the cutting depth for a smoother cut better suited for harder materials.

• Single Flute: Used for high-speed machining of high-volume material removal often in plastics or CFRP.

• Two Flute: Used for high-volume removal in slotting and pocketing non-ferrous materials.

• Three Flute: The same space between flutes as the two-flute Endmill but are stronger. Used for ferrous and non-ferrous materials.

• Four Flute: Stronger than the three-flute Endmill allowing for faster feed rates. They have less flute space than the 3-flute Endmill and produce smaller chips. These are most often used when cutting ferrous materials.

• Five Flute: Have smaller flute spacing than four-flute Endmills allowing for more strength than four-flute Endmills. These are better suited for high-efficiency milling and hard materials.

• Six Flute and Above: These are finisher Endmills that produce a very fine finish. They are also commonly used in dynamic or high-efficiency machining (HEM).

• Square Endmills

• Weldon Endmills

• Ball Endmills

• Radius Endmills

• Drill Endmills

• Roughing Endmills

• Rounding Endmills

• Undercutting Endmills

• Square Endmills have a 90-degree profile.

• They are used for all-around milling.

• Weldon Shank Endmills are produced with a Weldon flat to prevent any slippage.

• Ball Endmills (Ball Nose) have a round cutting surface used to mill contoured surfaces.

Corner Radius Endmills have a rounded corner to cut a specified radius.

• Finisher Endmills provide a smooth and polished finish in a single pass.

• Not suited for plunge cutting.

• Drill Endmills are used for spotting, drilling milling, and countersinking.

• Not recommended for drilling steel.

• Roughing Endmills also known as hog mills, are used to remove a large amount of material in a single pass.

• Roughing Endmills are available in course and fine pitch.

• Corner Rounding Endmills are used to mill round edges.

• The end of the tool is strengthened to reduce chipping.

• Undercutting Endmills are also known as lollipop cutters.

• They are versatile tools with many uses.

• It is distinguished from the drills in its application, geometry and manufacture.

• While a drill can only cut in the axial direction, an Endmill can cut in all directions.

• Endmills are used in milling applications such as profile milling, tracer milling, face milling, plunging, contouring, slotting, drilling, and reaming.

Important factors are

• Material to be Cut

• Operations to be Performed

• Number of Flutes

• Specification of Tool Dimensions

• Type of Tool Coating

Selecting the right Endmill will • reduce cycle time, • increase tool life, • produce a higher quality product

• Traditional Roughing

• Slotting

• Finishing

• Contouring

• Plunging

• High Efficiency Milling

• Work Material

• Material to be removed

• Surface finish required.

When used in the correct application, a coated tool will help to boost performance by providing the following benefits:

• More Aggressive Running Parameters

• Prolonged Tool life

• Improved Chip Evacuation

• Increase your feed

• Reduce your cutting forces by reducing speed and/or feed or axial and/or radial depth of cut

• Increase your clamping rigidity by changing over to a stub length end mill or improving your workpiece fixturing

• Change geometry - use an end mill with variable flute spacing or a small circular margin

• The cylindrical ground surface at major edges of drill fluteIf work surface looks uneven and rough, to improve the Surface Finish, possible resolutions are.

• Increase clamping rigidity

• Increase cutting speed

• Reduce feed

• Change to higher helix geometry

• Change to an end mill with more flutes

• Tool wear at cutting edges results in poor performance of tool.

• Reduce Spindle Speed - About 50% reduction in speed will almost double the tool life

• Check the feed – Right selection of feed rate will reduce Tool Wear

• Change tool material grade and/or add a coating