HSS DRILLS

Types of HSS Drills

PARALLEL SHANK TWIST DRILLS

(Jobber, Long, Extra Long, Stub, Step Drills, Sub Land Drills

and Core Drills)

TAPER SHANK TWIST DRILLS

(Standard, Long, Extra Long Step Drills, Sub Land Drills and

Core Drills)

Drill Standards : IS, JIS, ANSI, DIN and BS

Wide Range : Sizes from 0.30mm to 100mm (Dia) and

Length - up to 1200mm

Tolerances : h6 / h8 / Custom Tolerances

Material Grades used – M2, M35, M42 and ASP

View catalogCustomers of HSS Drills

- Maruti Suzuki India Limited

- Ashok Leyland Limited

- Hero Motocorp Limited

- Tata Motors Ltd

- Lucas TVS Limited

- Wheels India Limited

- Sundaram Fasteners Limited

- Craftsman Automation Ltd.

- Rail Coach Factory

- Integral Coach Factory

- Engine Factory

- Western Railway

- Bus Body Building

- Railway Cabin Shells

- Automotive

GALLERY

• Drill bits are rotated to get torque to create cylindrical holes in solid materials

• Universal Drill Bits - Variants are Twist Drill Bits, Step Drills, Unibits & Hole Saw

• Metal Drills Bits - Variants are Center and Spotting Drill Bits, Core Drill Bit, countersink bit, ejector drill bit, gun drill bit, Indexable Drill Bits

• Wood Drill Bits - Variants are Lip and Spur Drill Bits, Spade Drill Bits, Spoon Bits, Forstner Drill Bits, Center Bits, Auger Bits, Gimlet Bits and Adjustable wood bits etc.

• Diamond core bits

• Masonry Drill Bits

• Glass Drill Bits

• PCB Drill Bits

• Drills are handy tools that benefit everyone from a DIY to professional craftspeople.

• To ensure that you do not damage the material you are attempting to drill into, it is imperative that you have to use the correct drill bit.

Drill bits are made from different materials to suit their purpose.

• High-Speed Steel

• Cobalt Steel

• Tungsten Carbide Tipped

• Solid Tungsten Carbide

• Drill bits are made from different materials to suit their purpose.

• Using the right bit material enhances your efficiency.

• It also prevents you from losing money, purchasing a drill bit

• While almost all drill bits are made from metal due to its toughness, the difference comes in the metal composition.

• High-speed steel (HSS) is one of the most commonly utilized materials in the manufacture of drill bits.

• It is suitable for drilling wood, plastic, and soft metals.

• High Speed Steel is made from carbon steel with chromium and vanadium additives.

• M2

• M35

• M42

• M3

• 4341

• T15

• ASP2030

• Cobalt Drill Bits are especially adept at drilling through stainless steel and other tough materials.

• Cobalt has immense structural strength

• Cobalt has exceptional ability to withstand heat wear resistance

• Can go through just about any surface

• Black Oxide: helps the bit to retain lubricants to prevent the onset of rust.

• TiN Coated: TiN refers to titanium nitrate, which slows the progression of wear on bits that drill hard metals

• TiAIN Coated: titanium aluminum nitrate coating increases a bit’s resistance to abrasion and heat

• SG Coated: a silicone multilayer that helps a drill bit to penetrate dense metals.

• Indian Standard

• British Standard

• DIN – German Standard

• JIS – Japanese Standard

• ANSI – American National Standards

• Customer Standards

Addison manufacture the drills to different standards as above, however selection of standards is based on the requirement of hole tolerance & finish etc.,

| Type of Tools | Achievable Hole Tolerance |

| HSS General Purpose drills | H12 |

| HSS / HSCo Parabolic Flute Deep Hole Drills (PFX) | H10 |

| HSS / HSCo High performance TiN/ TiALN coated (ADX) | H9 |

| Solid Carbide High Performance TiN / TiALN coated (CDX) | H8 |

| Drill ∅ (mm) | H12 | H10 | H9 | H8 |

| ≤ 3 | 0 / +0.100 | 0 / +0.040 | 0 / +0.025 | 0 / +0.014 |

| > 3 ≤ 6 | 0 / +0.120 | 0 / +0.048 | 0 / +0.030 | 0 / +0.018 |

| > 6 ≤ 10 | 0 / +0.150 | 0 / +0.058 | 0 / +0.036 | 0 / +0.022 |

| > 10 ≤ 18 | 0 / +0.180 | 0 / +0.070 | 0 / +0.043 | 0 / +0.027 |

| > 18 ≤ 30 | 0 / +0.210 | 0 / +0.084 | 0 / +0.052 | 0 / +0.033 |

Based on depth of hole to be drilled, the right length of drill can be chosen.

• Stub Series Drill Bits : Suitable when Drilling depth is less than or equal to 3 times of the Drill Diameter (≤ 3xØ)

• Jobber Series Drill Bits: Suitable when Drilling depth is >3xØ and ≤ 5xØ

• Long Series Drill Bits : Suitable when Drilling depth is >5xØ and ≤ 7xØ

• Extra Long Series : Suitable when Drilling depth is >7xØ

To choose right series of drill for your application refer www.askaddisontools.com.

Among neat cut oil, water based coolant and kerosene it is based on the work material. To choose right coolant refer www.askaddisontools.com

| Material | Coolant |

| Aluminum & its alloys | Soluble Oil, Kerosene |

| Brass | Dry or Soluble Oil |

| Copper | Soluble Oil |

| Cast Iron | Dry or Compressed Air |

| Steel | Soluble Oil, Net Cutting Oil |

• Parallel Shank Twist Drill Bits

• Taper Shank Twist Drill Bits

• Brad Point Bits

• Masonry Bits

• Rivet Bits

• Spade Bits

• Installer Bits

• Step Bits

• Auger Bits

• Self-Feed Bits

• Forstner Bits

• Hole Saw

• Countersink Bits

• Plug Cutter

• Tile Bits

• Adjustable Wood Bit

• Annular Cutter

• Bits for Metal

• Glass and Tile Bit

• Hammer Bit

• Bullet Point Bits

• Axis

• Body

• Body Clearance

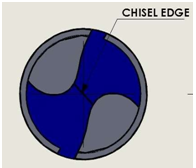

• Chisel Edge

• Chisel Edge Corner

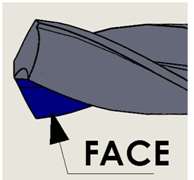

• Face

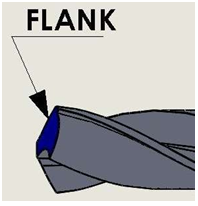

• Flank

• Flutes

• Heel

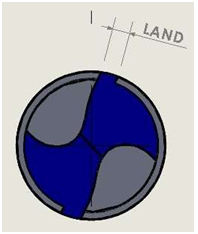

• Lands

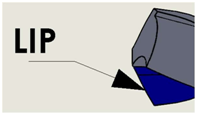

• Lip (cutting edge)

• Neck

• Outer Corner

• Point

• Right Hand Cutting Drill

• Shank

• Tang

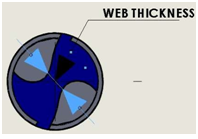

• Web

• Longitudinal centre line of the drill.

• The portion of a drill increasing from its extreme point to the origin of the neck, if present, otherwise increasing to the origin of the shank.

• The portion of the body surface which is reduced in diameter to provide diameter clearance.

• The edge formed by the intersection of the flanks. The chisel edge is also sometimes called the dead centre.

• The chisel Edge or Dead Centre acts as a flat drill and cuts its own hole in the work piece.

• A large amount of axial thrust is required to cut the hole. The chisel edge reduces the axial thrust and improves the location of a hole.

• Reduce the chances of producing oversize holes

• The corner produced by the intersection of a lip and the chisel edge.

• The portion of the flute surface adjacent to the lip one which the chip impinges as it is cut from the work.

• The surface at a drill point that extends behind the lip to the following flute.

• The groove in the body of the drill that gives lip.

• To Form the cutting edges on the point.

• To allow the chips to escape.

• To cause the chips to curl.

• To allow the cutting fluid to enter the cutting edges.

• The edge produced by the intersection of the flute surface and the body clearance.

• The cylindrical ground surface at major edges of drill flute.

• The edge formed by the intersections of the flank and face.

• Both lips should be at the same angle of inclination with the drill axis, 59° for general work.

• Both lips should be of equal length.

• Both lips must be given with the correct clearance.

• The portion between Body and Shank of a drill bit

• The corner formed by the intersection of the flank and face.

• The sharpened end of the drill, consisting of all that part of the drill which is shaped to produce lips, faces, flanks, and a chisel edge.

• A drill that cuts when rotating in a counter-clockwise direction viewed on the pointed end of the drill bit.

• The part of the drill bit by which it is held and driven.

• The central portion of a drill bit situated between the roots of the flutes and extending from the point toward the shank; the pointed end to the web (core) forms the chisel edge.

• Also known as high-speed bits, they resemble corkscrews and are some of the most popular bits.

• They are typically used to drill small holes.

• Their unique design allows them to channel dust from the hole as they work.

• Drill bit made with a tapered Shank is called Taper Shank Twist Drill

• Taper Shank Twist Drill’s has Taper Shank and they confirms to Morse Tapers MT1 to MT6.

• Taper Shank Twist Drill’s has Taper Shank and they confirms to Morse Tapers MT1 to MT6.

• The taper shank provides centering and holding the drill bit by friction in the tapered end of the spindle.

• The flattened end of the taper shank designed to fit inside a drift slot in the spindle, socket, or drill holder.

• Tang ensures a positive drive of the drill from the drill spindle.

• Brad point bits come in handy when you need to make clean and precise holes in wood.

• Their precision makes them a popular bit among woodworkers.

• These are what you use when looking to create holes in bricks, stones, or concrete.

• Due to the tough nature of those materials, masonry bits wear out quickly, meaning that you will need to replace them frequently.